(1036 products available)

A 3D printer auto leveling sensor is a vital component in the world of additive manufacturing. It plays a crucial role in ensuring that the 3D printer's print bed is perfectly leveled, which is essential for achieving high-quality prints. This sensor works by automatically measuring the distance between the print nozzle and the bed at multiple points. Based on these measurements, it adjusts the height of the nozzle during the printing process to compensate for any unevenness in the bed. This automation simplifies the leveling process for users, saving time and ensuring consistent print quality.

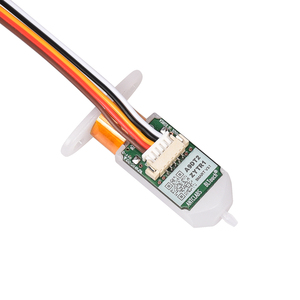

One common type of auto leveling sensor is the BLTouch, a popular choice among 3D printer enthusiasts. The BLTouch uses a retractable pin that is deployed to touch the bed and then retracted during the leveling process. This design allows for precise and reliable measurements, contributing to consistent print quality. Another type is the inductive sensor, which uses electromagnetic induction to detect the distance to the print bed. Inductive sensors are known for their accuracy and ability to work with various bed materials, such as metal or glass. Capacitive sensors, on the other hand, use the principle of capacitance to measure the distance to the bed. They are sensitive to the bed's electrical properties and can be effective on surfaces like glass or build surfaces coated with certain materials. Each type of auto leveling sensor has its strengths and may be preferred based on the user's specific needs and the printer's configuration.

The 3D printer auto bed leveling sensor offers several advantages, making it a valuable addition to any 3D printing setup. First and foremost, the primary benefit of an auto leveling sensor is the convenience it provides to users. Manually leveling a print bed can be a time-consuming and sometimes frustrating process, requiring precise adjustments to ensure an even surface. An auto leveling sensor eliminates this manual labor by automatically measuring and compensating for any unevenness in the bed. This not only saves time but also reduces the risk of human error, leading to more consistent print quality. It is especially useful for beginners who may find manual bed leveling challenging.

Additionally, an auto leveling sensor contributes to the overall print quality by ensuring that the first layer adheres properly to the bed. A level bed is crucial for achieving a successful first layer, which serves as the foundation for the entire print. By automatically adjusting the nozzle's height, the sensor helps prevent issues such as warping, poor adhesion, and inconsistent layer heights. This results in smoother bottom surfaces, improved part accuracy, and a higher overall success rate for prints. Moreover, users can experiment with a wider range of materials and bed surfaces. Having an auto leveling sensor allows users to work with materials that may require meticulous bed leveling, such as flexible filaments, and ensures consistent results.

Installing a BLTouch Ender3 or any other type of 3D printer auto leveling sensor typically involves several steps, beginning with the selection of the sensor type. Users need to ensure that the sensor is compatible with their 3D printer model. Following this, the sensor is mounted to the printer's carriage or frame in a location that allows it to accurately measure the print bed's surface. Wiring the sensor to the printer's control board is the next step, ensuring that the sensor's operation is integrated into the printer's firmware. Users may need to modify the firmware to enable automatic bed leveling and configure the sensor's settings, such as probing points and offsets. Once the hardware and software setup is complete, users can calibrate the sensor by running the auto leveling routine and fine-tuning any specific parameters to achieve optimal print bed leveling.