All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(24412 products available)

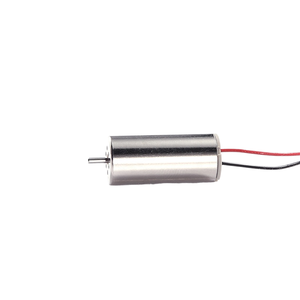

There are many 1020 motors differentiated according to function and application. The type of motor required depends largely on a company's operations in an important industry. The following overview outlines the most common 1020 motors by type.

A 1020 motor, specifically a DC brush motor, is a direct current electric motor with a brush system. This provides advantages for simple control and usage with basic electric current. This type of motor works especially well when used for low power requirements and with variable speed. The operational weaknesses include a restriction on longevity due to brush wear, which means it is often used in applications with less demanding operational conditions.

Compared to the 1020 DC brush motor, the brushless motor requires no maintenance because it has no brushes. This allows for operation for a longer time. This also allows for more effective use of the motor in many applications. This type of motor is more cost and time efficient due to the reduced possibility of mechanical failure that often occurs due to its design. This makes it particularly well suited for high-performance applications, such as electric cars.

The 1020 step motor is a type of electric motor that divides a full rotation into several equal steps. Every input pulse results in the motor shaft moving one step. Therefore, the operation of the motor is in the form of discrete steps rather than continuous rotation. This enables precise control over position and speed. Stepper motors are widely used in 3D printers, CNC machines, and robotics where accuracy is key.

A servo motor is a motor that can achieve very precise control of angular or linear position, velocity, and acceleration. This is done with the help of a feedback mechanism. The motor can rotate or move to a specified position and hold it accurately. It is widely used in robotic arms, CNC machinery, and any application that requires precise movement.

An 1020 AC induction motor utilizes alternating current (AC) to create magnetic fields in the stator. These fields cause the rotor to turn. It is a widely employed motor due to its rugged construction and reliability, particularly in industrial environments. Gratefully, induction motors are largely used for fixed-speed applications. They are useful in fan, pump, and compressor operations.

To select the right motor of this type, one must understand its features and specifications. This section looks into the features of the 1020 motor, which provide the basis of its performance capability.

Voltage

The 1020 motor is DC powered with a voltage of 12. This means it operates using a direct current electrical supply of 12 volts. This voltage measures the electric potential difference between two points in the circuit.

No Load Current

The current flowing into the motor when it is not attached to any kind of mechanical load is called no-load current (NLC). The NLC of the 1020 motor is 0.15 A. This means under this condition, it will draw an amperage equivalent to 0.15 when tension is applied.

Rated Speed

The speed of the motor when it is driving a rated load is called rated speed. The rated speed of the 1020 motor is 132 ± 10% rpm. This means that under normal conditions, the motor should rotate around 132 times every minute, with a possible variance of ±10%.

Output Torque

The motor can deliver torque to its load, and in this case, the output torque of the 1020 motor is 0.47 kg.cm. Torque is applied in the direction of the motor's rotation. This means the amount of torque or turning force the motor can exert is 0.47 kilograms at a distance of 0.1 meters from the center.

Rated Load

The requirement for the motor to work under optimal conditions is referred to as the rated load. The 1020 motor's rated load includes torque, speed, and electric current parameters. These values are associated with the motor's efficient operation. The rated torque is 0.47 kg.cm, the rated speed is 132 rpm, and the current is 0.4 A.

Secure Mounting

The first step to properly mounting the 1020 motor is to ensure it is securely mounted on a stable surface. The surface should be flat to ensure the motor operates correctly. Gratefully, the 1020 motor often has mounting holes or brackets for easy attachment to the surface. The stability of the surface will affect the motor's operation. This is because vibrations or movement can interfere with the motor's performance.

Connect the Power Supply

Once the 1020 motor is mounted, the next step is to connect the power supply. The 1020 motor operates on 12 volts. This means it should be connected to a 12-volt power source. The power source must be a battery or external power supply. Care and caution must be taken to ensure that the polarity is correctly connected. This is because a wrongly connected power supply will damage the motor.

Wiring the Control System

There are other installation contexts that call for a control system to manage the motor's operation, such as when more movement precision and control are required. These contexts dictate that the 1020 motor should be connected to a control system comprising a switch, potentiometer, or even a microcontroller-based system. This control system's role is to manage the movement and the speed in which it moves. When wiring, users must be keen on ensuring the proper connections by following a specific circuit diagram.

Attaching the Output Shaft

This attachment is not always necessary in every application. It is optional for some users. The output shaft can be attached to the motor if needed. This is done by connecting the shaft to the motor's output shaft. The connection can be achieved using couplings or other suitable fastening methods. The outputs, which include gears, wheels, or other mechanisms, need to be connected to the output shaft.

Testing

Before performing any major task or operation, testing is important, particularly in ensuring that the motor works properly. A first step after making the installations is to power the motor with no load attached. This is done to observe any abnormalities in the operation. During this test, the speed and movement should be checked. Also, checking for any unusual noise or vibration is important. Connecting a multimeter is also important to ensure the motor is receiving the right voltage.

Routine Inspection

Routine inspection involves examining the motor for any physical damage, such as wear and tear or loose connections. The mounting should also be checked for rust, which could weaken the motor's securing to the surface. Operationally, there should be an observation for unusual sounds or vibrations, which may indicate underlying issues. Basically, a routine inspection involves checking the general condition of the 1020 motor to ascertain it is working properly.

Lubrication

Some parts would require one form of lubricant or another to work properly and more efficiently, and the 1020 motor is not any different. Lubrication of components like bearings, gears, and shafts reduces friction and wear, which is important in enhancing their movements. Less friction means longer components' life, and less heat means no overheating. Users should use appropriate lubricants recommended by the manufacturers to ensure components work properly without damage.

Cleaning

Cleansing helps eliminate dust, debris, and other contaminants that may accumulate on the motor over time. Since these can affect the motor's performance, frequent cleaning is necessary to ensure the motor's unrestricted airflow. This is especially true for cooling mechanisms like fans and ventilation ducts. Cleaning the exterior of the motor prevents the buildup of dirt, which can cause corrosion. It is recommendable to use a dry cloth to clean a 1020 motor. A wet cloth might cause water to enter the motor and damage it.

Checking Electrical Connections

To operate well, the 1020 motor has to be well wired with an electrical connection. Therefore, this means that it has to be checked and, if need be, attended to. Frequent checking and, if need be, replacing worn or damaged wires, ensuring all connections are tight, will minimize electrical failure of the motor. Electrical failure means there is a power surge that might leave the motor incapacitated. Insulated connectors should be used to avoid unwanted accidents caused by electric shock.

Replacement of Worn Parts

Wear-out of some mechanical parts is inevitable, and it will happen one way or another. In this case, it is important to frequently check for signs of wear in bearings, brushes, and other components and replace them as necessary. Continuing to use worn parts will reduce their efficiency and affect the operational capability of the motor. In the case of the 1020 motor, a good example is its internal brushes.

The 1020 motors are widely utilized across a range of applications due to their versatility and efficiency. Below are some common scenarios where 1020 motors play a crucial role.

Since stepper motors are popular with CNC machines that require precise control over cutting tools, 1020 motors drive these machines. The 1020 step motor provides accurate positioning and movement, allowing for intricate designs. Its high torque and stable performance enable CNC machines to work on various materials. These materials include metal, wood, and plastic, to produce high-precision parts and components.

Robotics extensively employs 1020 motors due to their small size and high efficiency. These motors are commonly used in robotic arms, mobile robots, and drones for precise movement. The 1020 motor can provide the exact torque and speed required for intricate tasks such as picking and placing objects, moving parts, or navigating through environments. Its lightweight construction also makes it suitable for portable robots that need to carry their power sources.

Due to their capacity to control the position of the printhead or build plate, 1020 motors are commonly employed in 3D printers. 3D printers utilize two types of motors: stepper motors that move the printhead and the build plate to create an object and a DC motor that drives the filament. These motors work hand-in-hand to ensure the printer precisely follows the design and maintains the filament feed rate. This optimal utilization of 1020 motors ensures the printed models are accurate and of high quality.

Electric vehicles (EVs) rely on DC brushless motors for many of their functionalities. For instance, the 1020 motor, especially the brushless variant, is widely used in electric vehicles. It is appreciated for its efficiency and low maintenance needs. These motors drive the vehicle's main propulsion system to offer smooth acceleration, better speed, and an increase in distance traveled on a given amount of energy. Also, 1020 motors are used in smaller electric vehicles like e-bikes and scooters.

Industrial automation employs AC induction motors in mechanical systems like conveyor belts and pumps. These systems require reliable and long-running motors to drive the frameworks employed in manufacturing. The 1020 motor provides the needed constant speed with minimal maintenance. Furthermore, these motors are used in ventilators and compressor systems to ensure adequate fluid and air movement.

Ensuring the quality and durability of a 1020 motor is very important, especially for users to ascertain the operational efficiency of the motor and its reliability under various working conditions of the 1020 motor. Below are some essential factors that underline the 1020 motors' quality and durability.

The durability of a 1020 motor depends greatly on the quality of the material the manufacturers used to construct the components of the motor. The components, including the rotor, stator, and housing, should be made from robust materials like steel or high-grade aluminum. These materials, among others, have what it takes to withstand mechanical stress, wear, and tear, and temperature variations.

As necessary as the material is, the workmanship of assembling the 1020 motor determines how well the components are put together. When the components are properly manufactured and well aligned, the resulting motor will not only work smoothly but efficiently, too, and with less mechanical strain. This reduces stress on components and increases their lifespan.

Most 1020 motors have built-in electronic or thermal protection circuits to guard against overloading, overheating, and short-circuiting. These protections are important because they stop operational failures and potential damage to the motor. These protective elements monitor the current and temperature, and when they exceed set thresholds, they automatically shut down the motor to prevent damage.

Quality assurance requirements are fulfilled by testing and certifications according to industry standards. These tests examine the efficiency, safety, load capacity, and durability of the 1020 motors in several application scenarios. Certifications from recognized organizations indicate that the motor not only meets but also has the potential to exceed the quality and safety requirements. This enhances the 1020 motors' reliability for those who use them.

Subjecting the 1020motor to different environmental conditions, such as moisture, dust, and extreme temperatures, affects the durability of the motor. A good motor should have standard IP ratings that attest that it is well protected from dust particles and moisture. This makes the motor suitable for outdoor applications and in industrial areas where contaminants are abundant and extreme working conditions are the order of the day.

A1: DC brush, brushless, and step-up motors are used for small precision operations and medium loads, while AC induction motors are meant for large industrial areas. CNC machines, robotics, 3D printers, electric vehicles, and industrial automation employ the 1020 motors.

A2: Cleaning, lubricating, and inspecting for wear, checking electrical connections, and replacing worn-out parts are some of the ways to properly maintain the 1020 motors.

A3: There are overloads, heat, and short circuits that protect the 1020 motors, as well, of course, as ensuring they are appropriately powered and cooled to prevent any eventuality that comes from these threats not being handled.

A4: High-quality materials, proper workmanship, protective circuits, routine testing, and environmental resistance contribute toward the Quality & Durability of the 1020 motors.