(2293 products available)

The 1.5g servo is a miniature and lightweight device used in radio-controlled models, toys, and other applications where space and weight are critical. It is designed to provide precise control of movement while being very light, making it ideal for applications like micro drones, rc cars, planes, and robotics. These servos are often used in models and devices where traditional servos would be too heavy and bulky. The 1.5g weight indicates the servo's lightweight nature, allowing for better performance in applications where minimal weight is crucial.

1.5g servos come in different types to cater to various applications and performance requirements. These types differ in terms of technology, functionality, and design:

Analog Servos

These are the basic type of servos. They use a simple circuit that consists of a potentiometer, a motor, and a control chip. They are known for their reliability and simplicity. These are ideal for basic applications where precision and speed are not of utmost importance. They are usually cheaper than digital servos. However, they have lower torque and slower response times compared to digital servos.

Digital Servos

Digital servos have a microprocessor that improves the signal processing speed. This results in higher accuracy, greater torque, and faster response times. They are perfect for advanced applications such as robotics, drones, and RC vehicles. These applications demand precise control and higher performance. They provide more consistent performance under varying loads.

Mini Servos

Mini servos are smaller than standard servos but offer similar functionality. They are designed for use in compact devices such as small RC cars, planes, and helicopters. These devices can work better in applications with limited space requirements. They are easier to install in small and space-constrained projects.

Micro Servos

Micro servos are smaller than mini servos. They are used in even more compact devices and applications, such as indoor RC cars, small drones, and robotic arms. They are ideal for projects that demand precise control in very limited spaces. They are lightweight and easy to integrate into small devices.

Coreless Servos

Coreless servos have a coreless motor that allows for a lighter and more compact design. They offer better efficiency, faster speed, and smoother operation. This makes them ideal for high-performance applications with limited space. These devices have a higher power-to-weight ratio and a quicker response time. This ensures better performance in demanding situations.

Torque Servos

Torque servos are specially designed to provide high torque, whether at low speeds or high speeds. They are used in applications that need to move heavy loads or in high-payload scenarios. These servos ensure that there is consistent torque delivery to manage demanding tasks efficiently. They can control larger or heavier devices without straining or stalling.

Waterproof Servos

Waterproof servos are sealed to prevent water and dust from entering. They are ideal for applications exposed to harsh weather conditions, such as boats, off-road vehicles, and outdoor robots. They can be used in all environments without worrying about damaging the device. They are resilient and can work in environments with high humidity or dust levels.

When selecting a 1.5g micro servo motor for a project, there are several critical factors to consider that will ensure the motor meets the application's needs. To this end, the buyer should consider the servo size and weight. The tiny size and light weight of 1.5g micro servo make them suitable for applications with low weight requirements, such as indoor drones, RC planes, and micro robotic arms. The actuator's weight becomes crucial when adding many motors to a mobile device or robotic arm; thus, it is advisable to use lighter ones.

Also, the torque capability should be considered when choosing a small servo motor. Torque determines how much load a servo can move. For example, higher torque is needed to lift heavier objects or operate at larger radii. Therefore, servos with different torque ratings should be used based on the load to be moved. Additionally, the control range of the servo arm is also essential since it impacts the kind of motion that can be achieved with the device. More extended control ranges allow more complex movements, while shorter ones may work for simple designs.

Moreover, the speed of the 1.5g mini servo is essential in applications requiring quick reactions or fast-paced movements. Servos with high-speed ratings are better for dynamic tasks, but there may be a trade-off between speed and torque. The power supply and voltage compatibility of the micro servo must align with the system's requirements since they affect performance and efficiency. Usually, 1.5g micro servos operate on 3V to 6V DC, so ensure that it is within this range to prevent it from burning out the motor. Additionally, the control mechanism should be considered, whether using PWM signals or analog controllers, to ensure seamless integration into the project's electronic components.

Finally, consider how durable and built-up quality the micro servo is. This is because the servo must withstand wear and tear, especially in applications with rough handling. It is also essential to check the manufacturer's specifications and recommendations when selecting a 1.5g micro servo.

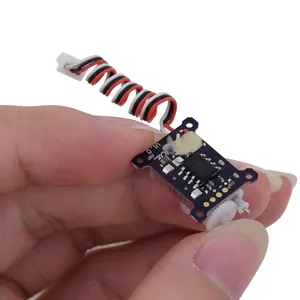

The design of a 1.5g micro servo is what makes it a useful tool in various applications. Also, it helps to ease its integration into different systems. Here are some key features and their designs:

Size and Weight

A 1.5 g micro servo is small and compact in size. This makes it suitable for use in applications that require servos with limited space. Its small size allows for precise control of movements. The weight of the servo is also low. This minimizes the overall weight of the system it is being used in.

Control and Precision

The small servo motor provides accurate positioning and control of movements. This is because it has built-in potentiometers that measure the angle of rotation. Also, these servos come with control systems that ensure smooth and precise movements. The high precision of the small servo motor allows its use in robotics, RC vehicles, and other applications.

Power and Performance

A micro servo, despite its small size, offers high power and performance. It has a strong motor that offers high speed and torque. This allows it to work well in demanding applications. Also, the servo has a durable casing that protects it from dust, moisture, and other elements.

Battery and Power Supply

Most small servos are powered using standard 4.5V to 6V batteries. Some servos also come with a built-in rechargeable battery. This eliminates the need for frequent battery replacements. The power supply options make the servo versatile and convenient to use.

Mounting and Installation

A small servo has a simple mounting system that eases its installation. It has standard mounting holes, brackets, and other accessories that ease its installation. This makes it easy to integrate into various systems and designs.

Applications

Since micro servos have a compact design, they can be used in many applications. For instance, in RC cars, planes, and drones for steering, throttle control, or rudder control. They are also used in robotics for precise and accurate movements of robotic arms and legs. Small toy animals also use servos for realistic movements.

Some of the 1.5G servos have the following safety features:

Overload Protection

Some servos have an overload protection mechanism that automatically shuts down the device when it gets overloaded. This protects the servo from damage. It also prolongs its lifespan.

Heat Dissipation

Heat insulation materials usually build servos' resistance to shock and impacts. This helps the servo motor operate at high efficiency for a long time. It also prevents any damage caused by overheating.

Waterproofing

Some servos have a waterproof rating. This means they can work properly in wet conditions without getting damaged.

The quality features of 1.5G servos include:

Quality Materials

The servo is made from quality materials, including aluminum alloy, metal, plastic, and carbon fiber. This makes the servo durable and long-lasting.

Reinforced Construction

Some servos, like the metal gear servo, have reinforced construction. This makes the servo handle higher loads and operate efficiently for a long time.

Premium Quality

1.5g servos use premium quality, high-strength carbon fiber material. The carbon fiber makes the servo lightweight, rigid, and strong. It also offers excellent thermal conductivity and electrical insulation.

Certifications

Some servos have quality certifications like CE and RoHS. These certifications show that the servo has been quality tested following industry standards.

Are 1.5g servos suitable for all types of RC vehicles?

No, 1.5g servos are not suitable for all types of vehicles. While they work well for small and lightweight RC vehicles, they may not be ideal for larger vehicles that require more power and torque to control effectively.

How do buyers determine the correct servo size for an RC vehicle?

Buyers should consider the vehicle's size, weight, and type, as well as the terrain it will be used on. Lightweight and small vehicles can use a 1.5g servo, while heavier and larger vehicles should use a more powerful servo.

Can buyers use the same servo for multiple applications?

Although it is possible to use the same servo for various applications, it is not recommended because each application has unique requirements. Using the same servo for different applications can lead to poor performance and damage to the servo.

How long do servos typically last?

The lifespan of a servo depends on several factors, such as usage, maintenance, and quality. A well-maintained servo can last for several years.