Understanding Crusher Blades

Crusher blades are integral components of the plastic processing industry, utilized predominantly in plastic crushing machines. These blades are designed to disintegrate various types of plastic materials into smaller granules or pieces, facilitating easier recycling and disposal. The efficiency and effectiveness of plastic size reduction depend significantly on the quality and type of blades used.

Types and Applications

The variety of crusher blades available caters to different industrial needs. They are commonly found in settings such as manufacturing plants and building material shops. Their applications extend to machinery repair shops where they are essential for the maintenance of plastic crushing equipment. The blades come in various forms, including those for plastic & rubber machinery parts, highlighting their versatility across different sectors.

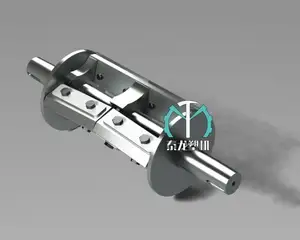

Features and Materials

Crusher blades are crafted from robust materials like stainless steel, ABS, and PP to ensure durability and longevity. Stainless steel blades, in particular, offer resistance to wear and corrosion, making them suitable for continuous industrial use. The design of these blades varies, with some featuring specialized cutting edges for enhanced performance in specific recycling tasks.

Advantages of Crusher Blades

The use of high-grade materials in crusher blades provides several advantages. They maintain sharpness over prolonged periods, reducing the need for frequent replacements. This durability also ensures consistent performance in breaking down plastic materials, which is crucial for the efficiency of recycling operations. Furthermore, the availability of both new and used options allows for flexibility in procurement, depending on the operational requirements and budget constraints.

Selection Criteria

When selecting crusher blades, it is important to consider the type of plastic material to be processed and the machine compatibility. Blades are designed to fit specific machines and their engines or motors, ensuring seamless integration and optimal performance. The choice between new and used blades will also depend on the intended application and the demand for precision in the crushing process.

Environmental Impact

The role of crusher blades extends beyond mere functionality; they are pivotal in promoting environmental sustainability. By facilitating the recycling of plastic materials, these blades help in reducing the ecological footprint of plastic waste. Their contribution to the recycling industry underscores the importance of selecting the right blades for effective waste management.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4