| Quantity (pieces) | 1 - 5000 | > 5000 |

| Lead time (days) | 15 | To be negotiated |

Ceramic honeycombs are used in regenerative thermal oxidizer (RTO) and regenerative catalytic oxidation (RCO) devices to destroy hazardous air pollutants (HAPs), volatile organic compounds (VOCs) and odorous emissions etc.

According to different process requirements of exhaust gas treatment (RTO, RCO), our company develop and produce a variety of materials and sizes of ceramic honeycomb products. Products have large surface area, small resistance loss, low thermal expansion coefficient, high water absorption, good crack resistance, moderate millipore aperture and other characteristics; have been widely used in RTO, RCO equipment at home and abroad.

Material: Alumina porcelain, dense alumina, dense cordierite, porous cordierite, porous mullite, stoneware porcelain, etc.

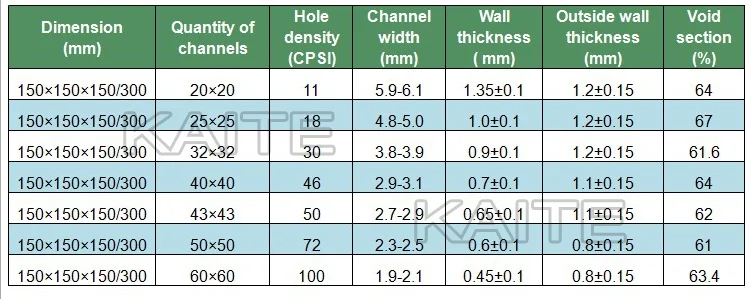

Size: 100×100×100 mm, 100×150×150 mm, 150×150×150 mm, 150×150×300mm and others.

Quantity of hole: 20×20, 25×25, 32×32, 40×40, 43×43, 50×50, 60×60 and others.

Hole shape: Square, rectangular, hexagonal, circular, triangular and so on.

We can also be customized according to customer requirements.

| Item |

Alumina Ceramic |

Loosen Mullite |

Compact Cordierite |

Loosen Cordierite |

Stoneware Porcelain |

|

| AL2O3 |

% |

52.0 |

68.3 |

25.5 |

35.4 |

30.4 |

| SiO2 |

% |

43.3 |

28.9 |

57.2 |

51.5 |

66.1 |

| MgO |

% |

0.1 |

0.2 |

7.9 |

11.5 |

0.13 |

| Other |

% |

<3.5 |

<2.0 |

<3.0 |

<1.5 |

<3.0 |

| Material density |

g/m3 |

2.68 |

2.31 |

2.42 |

2.16 |

2.47 |

| Loose density |

Kg/m3 |

965 |

832 |

871 |

778 |

889 |

| Coefficient of thermal expansion |

×10-6/ K |

6.2 |

6.2 |

3.5 |

3.4 |

4.8 |

| Specific capacity |

J/Kg K |

992 |

998 |

942 |

1016 |

897 |

| Thermal conductivity |

W/mk |

2.79 |

2.42 |

1.89 |

1.63 |

1.37 |

| Resistance to fluctuated temperature |

K |

Max 500 |

Max 550 |

Max 500 |

Max 600 |

Max 500 |

| Softening temperature |

°C |

1500 |

1580 |

1320 |

1400 |

1380 |

| Highest working temperature |

°C |

1400 |

1480 |

1200 |

1300 |

1280 |

| Average thermal capacity |

KWh/m3K |

0.266 |

0.231 |

0.228 |

0.219 |

0.222 |

| Porosity ratio |

% |

0.8 |

26.0 |

0.4 |

15.0 |

0.6 |

| Acid resistance |

% |

0.2 |

2.5 |

5.0 |

16.7 |

0.3 |

Honeycomb Ceramic for RTO (Heat Media)

Regenerative thermal oxidizer (RTO) is effective exhaust air treatment for a wide range of processes. The system uses a bed of ceramic material (e.g. Honeycomb ceramic heat exchange media) to absorb heat from the exhaust gas and use the captured heat to preheat the incoming process gas stream. This significantly lowers overall operating costs. The regenerative thermal oxidizer (RTO) converts volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) to carbon dioxide and water vapor through thermal oxidation.

Specificationof honeycomb ceramic for RTO (Heat media)

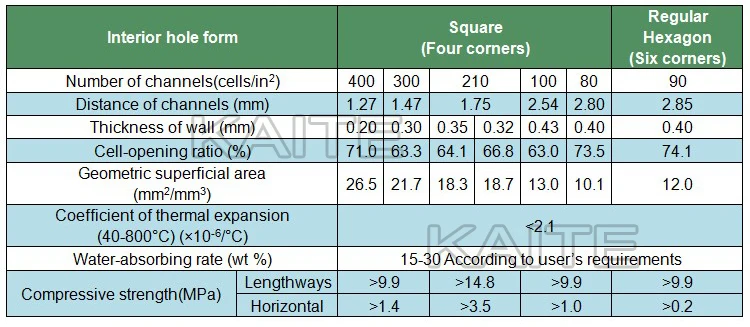

Honeycomb for RCO (Catalyst Support)

Regenerative catalytic oxidizer (RCO) is improved on basis of RTO structure, added in the oxidizers boiler with the layer of special catalyst material. Using catalytic oxidation to provide sufficient heat required to destroy VOC. This technology can reduce the RTO system operating temperatures, improve efficiency and reduce the fuel consumption.

Regenerative catalytic oxidizer (RCO) destroys air toxins and Volatile Organic Compounds (VOCs) that are discharged in industrial process exhausts. The RCO system achieves VOC destruction through the process of catalytic oxidation, converting the VOCs to carbon dioxide and water vapor, recycling released energy to reduce operating costs.

Honeycomb thermal store catalyst ceramic is used for waste gas treatment (RTO/RCO) of the different requirements, selecting many kinds of new highly effective ceramic material to make. It has the properties of corrosion resistances, high specific surface area, low resistance, low thermal expansion coefficient, good thermal conductivity and thermal-shock resistance performance.

Technical data of honeycomb catalyst substrate for RCO

Every payment you make on Alibaba.com is secured with strict SSL encryption and PCI DSS data protection protocols

Claim a refund if your order doesn't ship, is missing, or arrives with product issues